VIBARREL®

VIBARREL bulk treatment system®

Application

Surface treatment for bulk parts in a vibrating basket.

Advantages of VIBARREL technology®

- Even distribution over the surface of each part .

- Gentle treatment, no damage to your delicate parts.

- Improved electrolyte exchange.

- Reduced consumption of precious metals compared with a barrel solution.

- Reduced drive from one tank to another.

How does vibration work during surface treatment?

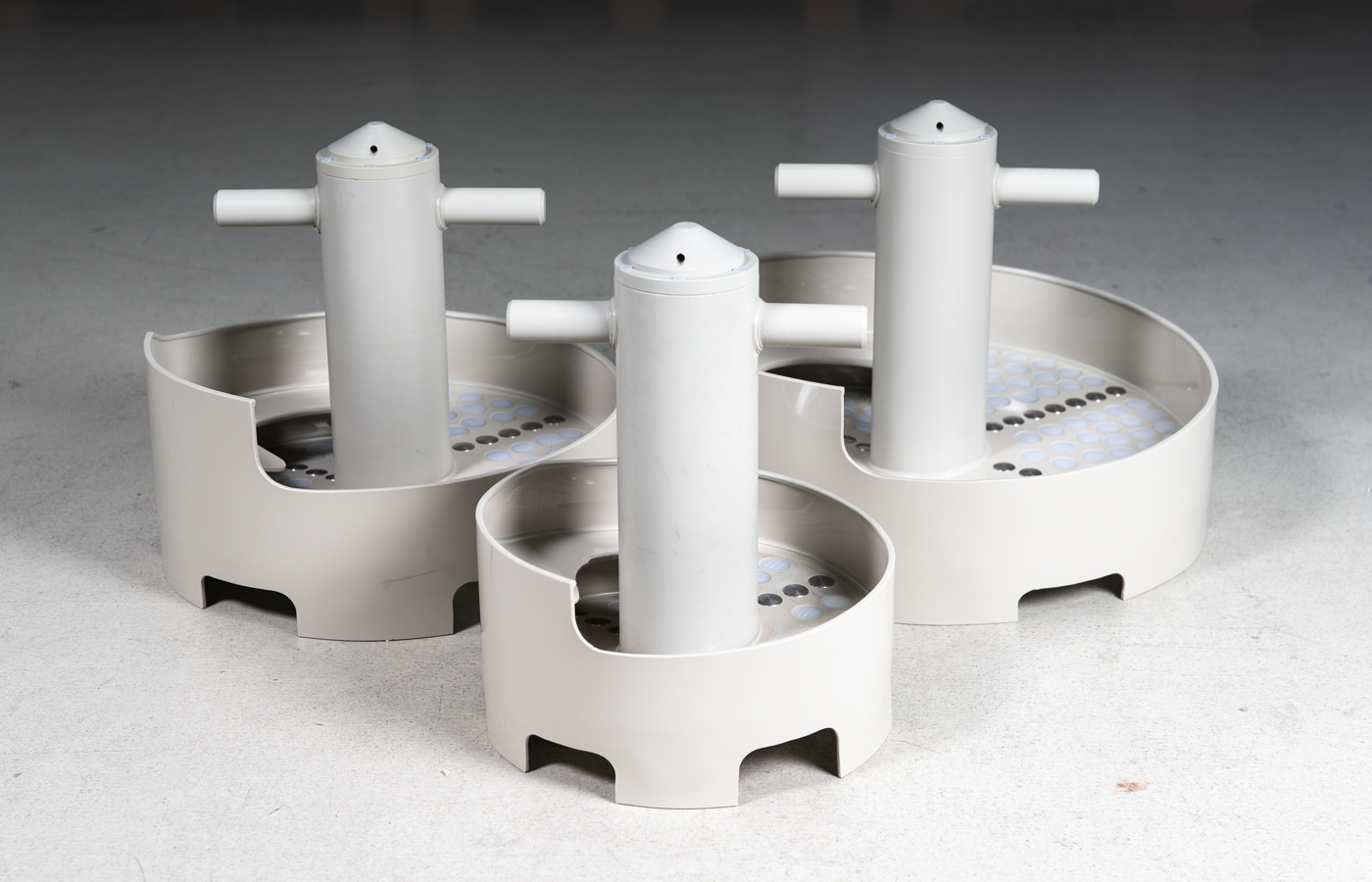

- The vibratory unit consists of a cylindrical basket, which is attached to the top of an axial and tangential oscillator. The frequency and amplitude of agitation can be adjusted independently of each other.

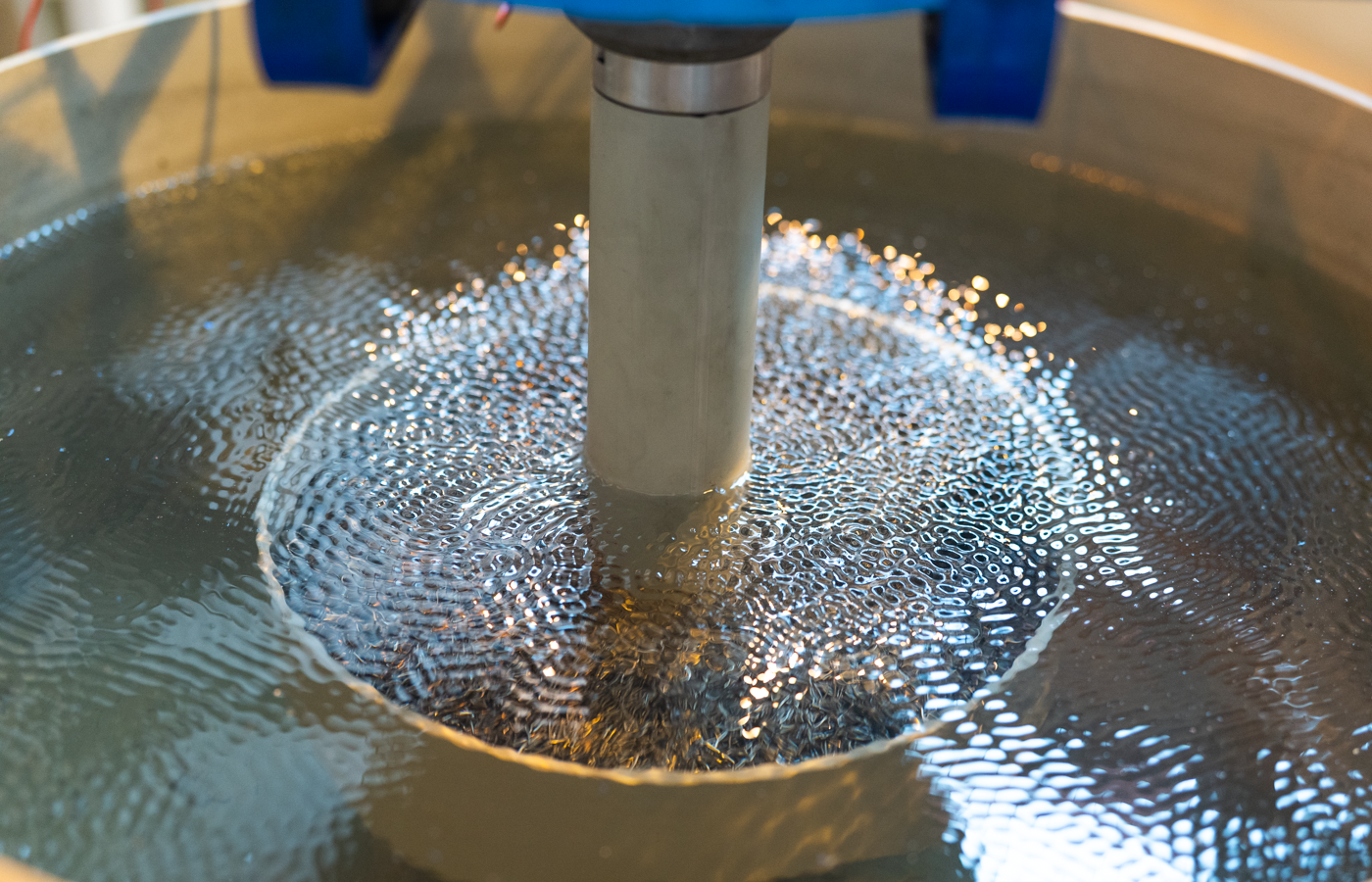

- The vibration ensures that the products move uniformly and slowly around the axis of the basket, providing gentle mixing and agitation. During agitation, the products come into contact with the cathode contacts located on the bottom of the basket and maintain electrical contact throughout the movement.

- The perforated plastic capsules on the bottom of the basket allow electrolyte exchange. This ensures constant current density and uniform treatment.

-

The Vibarrel can be moved from bath to bath, either manually or semi-automatically by a bread system, or automatically by a robot.

Do you have a specific request? Let's talk about it.

We've been helping companies create their production equipment since 1975. Our specialists will be able to give you the best advice to create the machine you need for years to come.